The Engine Combustion Network collaborates with various institutions to share experimental data, diagnostics, and computational results. This section contains a collaborative data search utility as well as different web-pages for the institutions who have contributed experimental data. Information regarding the facilities of the institutions that have contributed to the ECN follows:

The Engine Combustion Network collaborates with various institutions to share experimental data, diagnostics, and computational results. This section contains a collaborative data search utility as well as different web-pages for the institutions who have contributed experimental data. Information regarding the facilities of the institutions that have contributed to the ECN follows:

Constant Flow test rigs are high temperature and high pressure test chambers, which can simulate the thermodynamic conditions obtained in a Diesel engine, under steady conditions. CMT and Caterpillar both use constant flow test rigs.

The facilities at Caterpillar and CMT-Motores Térmicos have vessels that are able to reach ambient gas temperatures and pressures up to 1000 K and 150 bar.

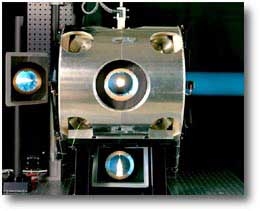

Preburn Combustion vessels are used to generate high temperature, high pressure gases. The ambient pressure, temperature and species at the time of injection are varied by igniting a premixed combustible-gas mixture that burns to completion. Following the spark-ignited premixed combustion, the combustion products cool over a relatively long time (~500 ms) due to heat transfer to the vessel walls and the vessel pressure slowly decreases. IFPEN, Sandia, and TU/e use pre-burn type combustion vessels.

The facility at Sandia National Laboratories has a vessel that is able to range ambient gas temperatures from 450 K to 1400 K, densities from 1 kg/m3 to 60 kg/m3, and pressures up to 350 bar.

The facility at IFP Energies nouvelles has a vessel that is able to reach ambient gas densities of 30 kg/m3, pressures of 150 bar, and temperatures of 1300 K.

The facility at Eindhoven University of Technology (TU/e) has a vessel that is able to reach ambient gas densities of 32 kg/m3, pressures of 300 bar, and temperatures of 1300 K.

Other:

The facility at Argonne National Laboratory has a vessel that is able to reach ambient pressures of 30 bar and temperatures of 300 K.