At each experimental condition, the flame lift-off length, H, was measured as described in Refs. (Siebers, 2001; Higgins, 2001). Time-averaged, line-of-sight images of light emitted from a burning fuel jet at 310 nm were acquired with an intensified CCD camera using a 310 nm band-pass filter (10 nm FWHM). A major source of light emission at 310 nm is chemiluminescence from excited-state OH (OH*) (Higgins, 2000). Unlike ground-state OH, which exists as an equilibrium product in regions of high temperature, OH* is short-lived and results from chemical reactions in near-stoichiometric, high-heat-release regions. Soot luminosity also emits broadband emission with significant emission at 310 nm, but OH chemiluminescence dominates in the lift-off length region where soot has not yet formed (Higgins, 2000). OH chemiluminescence therefore provides a good marker of the lift-off length. Time-averaging of the images was accomplished by starting the camera after autoignition was completed and the tip of the fuel jet passed through the field of view of the camera, and stopping the camera prior to the end of injection, similar to averaging of soot extinction measurements.

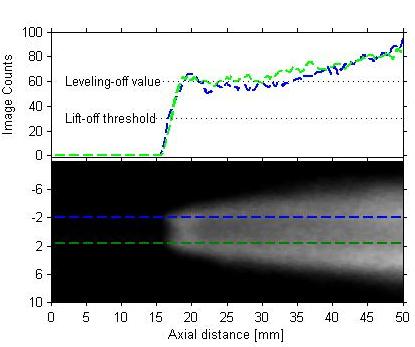

Fig. 4.4.1. Example image of time-averaged OH chemiluminescence. Ambient conditions: Ta 1000 K, ρa 14.8kg/m3, 21% O2. Injector conditions: 1500 bar above ambient, 0.1 mm nozzle, n-heptane

An example image of the time-averaged 310-nm emission is shown in Fig. 4.4.1. OH chemiluminescence begins at a well-defined distance from the injector orifice, initially rising very sharply, then leveling off, as shown in Fig. 4.4.1. Two lobes of intense chemiluminescence on the top and bottom of the jet are typical near the lift-off length. The lift-off length was determined by finding the distances between the injector and the first axial locations above and below the spray centerline with an intensity greater than approximately 50% of the leveling-off value, as shown in Fig. 4.4.1. The average of these two axial distances is defined as the lift-off length. Instantaneous OH chemiluminescence images showed that the lift-off length, defined in this manner, was the mean location of instantaneous fluctuations in OH chemiluminescence (Higgins, 2000). High-speed movies of chemiluminescence also show that the lifted reaction zone quickly stabilizes after autoignition and remains relatively stationary throughout the time of injection.

Fig. 4.4.2. Chemiluminescence movie. Ambient conditions: Ta 850 K, ρa 14.8kg/m3, 21% O2. Injector conditions: 1500 bar above ambient, 0.1 mm nozzle, n-heptane

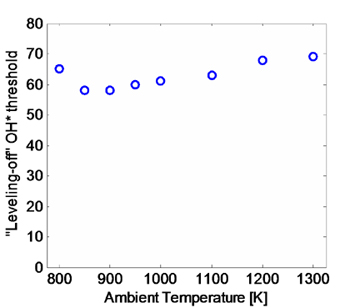

Threshold intensities and camera gain were varied with ambient oxygen concentration to account for differences in chemiluminescence intensity. However, threshold intensities and camera gain were held constant as ambient temperature was varied. This was justified because the “leveling-off” value of OH chemiluminescence intensity did not change significantly with ambient temperature (Fig. 4.4.3). A possible explanation for this effect is that the line-of-sight path length through combustible mixtures increases with decreasing ambient temperature because lift-off length increases, which compensates for the decreasing flame temperature (expected to scale with chemiluminescence).

Fig. 4.4.3. “Leveling-off” values of time-averaged OH chemiluminescence (see Fig. 4.4.1). Conditions same as Fig. 4.4.1 except ambient temperature.

For the sake of comparison to model predictions, temperature and OH mole fraction are expected to be useful model parameters for the OH chemiluminescence experiments. Both temperature and OH mole fraction are expected to increase significantly with the onset of high-temperature chemistry (and chemiluminescence). In addition, the threshold value for these parameters should not make a major difference in computed lift-off length because of the chemiluminescence rise is very rapid, experimentally. However, the lift-off length diagnostic is a line-of-sight technique and so line-of-sight reduction of modeled data is expected to be most useful. In addition, OH chemiluminescence is not directly proportional to ground-state OH number density as the OH chemiluminescence is the result of high-heat-release chemical reactions.

Compression Heating of Ambient Gas– The ambient gas temperature and density in the combustion vessel increase after autoignition and continued fuel injection. The increase is caused by a pressure increase from the burning fuel spray which compresses unmixed ambient gas. These changing ambient gas conditions during injection can cause the lift-off length to decrease with time if the changes are large enough (Higgins, 2000). The pressure rise caused by the diesel fuel injection is typically small because of the large mass of ambient gas in the combustion vessel relative to the mass of fuel injected. Estimates for the change in ambient temperature were made to process lift-off length measurements. The ambient temperature and density estimates were made using isentropic compression and the measured pressure during the time of image acquisition (Siebers, 2001). Two ambient temperatures are therefore given in the database: one before ignition and the other after ignition (Data Def.). Conditions where the temperature rise is more significant include low ambient density (low mass in vessel) or large-nozzle, high-injection-pressure conditions (high mass of fuel injected).