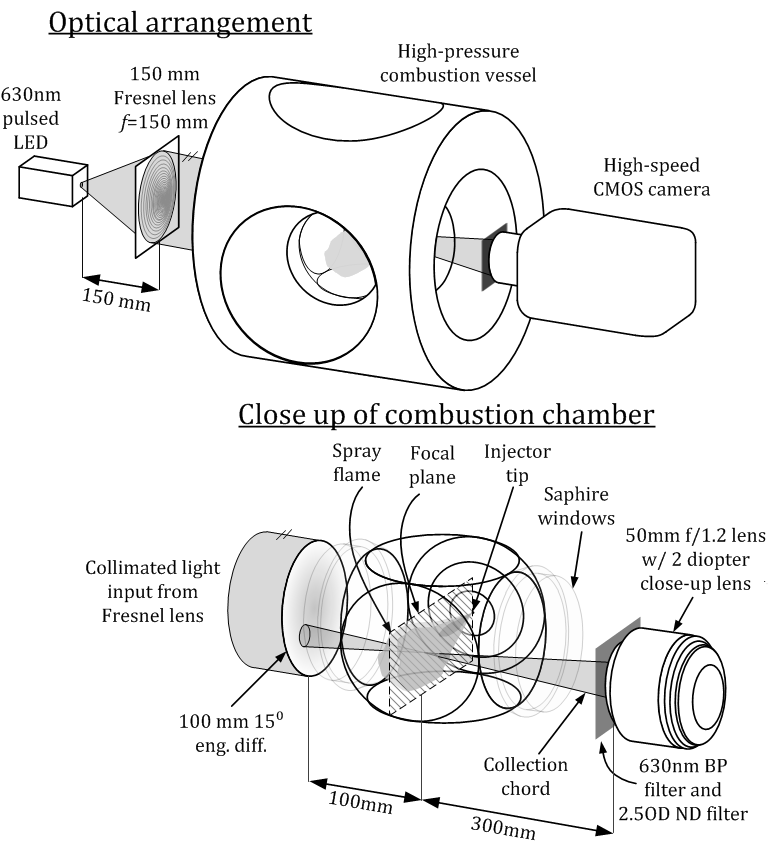

Although both Mie-scattering and diffused back-illumination (DBI) imaging may be used for liquid-phase measurements, the recommendation is to use DBI or laser extinction with sufficient beam-steering accommodation. This is also recommended by the SAE J2715 standard for gasoline spray characterization. DBI uses the extinction produced by the spray droplets to provide a measure related to the liquid volume fraction along the path of the light. The advantage for quantification is that there is self-calibration for the initial intensity. In engine (high-pressure, high-temperature) environments, care must taken to ensure that the diagnostics is not sensitive to vapor-phase beam steering from temperature/refractive index gradients. The diffuser angle and collection angle need to be quantified for a given setup, and the camera needs to be configures to accurately measure background intensity (with no transmitted DBI light). An example setup is shown below.

Fig. Diffused back-illumination for high-speed extinction imaging

Recommendations for liquid-phase penetration measurements

Extinction data are to be processed for “projected liquid volume” in the cross-stream direction, or integral(liquid volume fraction * dy), as described in the ECN5.9 presentation of Pickett (slides, recording at 1:38:45). Because of uncertainties associated with the experiment, two different criteria should be used to define the liquid-phase penetration:

- 0.2e-3 mm3 liquid / mm2

- 2.0e-3 mm3 liquid / mm2

Please see example comparisons of Mie scatter and DBI imaging for more technical details regarding the Mie-scattering and DBI measurements.