Gasoline Computational Method

This page contains resources and tools used for computational modeling of gasoline sprays. Here the modeling method only focuses on late injection Spray G condition, while the method for flash-boiling spray is not provided yet.

While similar work has been reported for diesel sprays, the operating conditions for gasoline multi-hole injector are completely different from those for diesel injector. Moreover, the overall spray angles for gasoline applications are generally much narrower (~60°-95°) compared to those associated with diesel applications (~140°-160°). These relatively narrow spray angles result in close proximity of adjacent spray plumes, often leading to significant plume-to-plume interactions. Close proximity of adjacent plumes is a necessity in the gasoline application to promote flame propagation from a fixed ignition location. These plume-to-plume interactions significantly influence air entrainment and preclude, causing spray collapse.

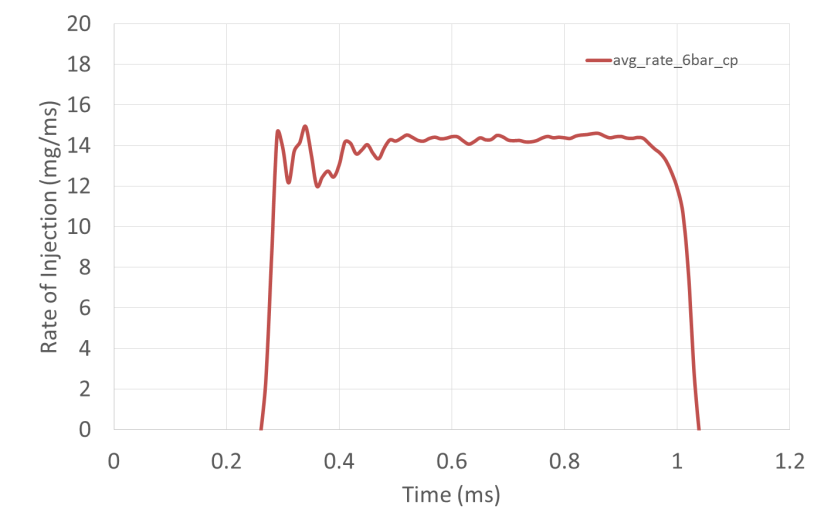

For direct-injection with stratified combustion, the ambient pressure and temperature for gasoline fuel injector can be close to those for diesel fuel injector. The larger ambient pressure leads to increased plume-angle, thereby strengthening the plume-to-plume interactions. This is barely reported by the diesel community that often uses simplified single-hole injectors for fundamental study and this is a particular challenge for modeling multi-hole direct-injection gasoline sprays. Below is the target condition and rate of injection. The data points for the graph below are avalaible for downloading in a excel file.

Figure 1: Rate of injection